- Introduction to Thermoelectric Materials

- What are Thermoelectric Materials?

- Key Properties of Thermoelectric Materials

- Types of Thermoelectric Materials

- Bismuth Telluride (Bi2Te3)

- Lead Telluride (PbTe)

- Silicon-Germanium Alloys (SiGe)

- Skutterudites

- Other Emerging Materials

- Summary Table of Common Thermoelectric Materials

- How Thermoelectric Generators Work

- Advantages of Thermoelectric Generators

- Limitations of Current Thermoelectric Technology

- Applications of Thermoelectric Materials

- Waste Heat Recovery in Industry and Automobiles

- Space Exploration

- Portable and Wearable Electronics

- Cooling and Temperature Regulation

- Table: Key Applications and Corresponding Thermoelectric Materials

- Future Trends and Innovations

- Challenges Facing Thermoelectric Materials

- List of Challenges

- How to Evaluate a Thermoelectric Material’s Performance

- Typical ZT Values for Popular Materials

- Practical Tips for Using Thermoelectric Materials

- Conclusion

Introduction to Thermoelectric Materials

Thermoelectric materials have steadily gained attention in recent years for their unique ability to convert heat directly into electrical power. This fascinating property opens doors to new, efficient ways of energy harvesting and management. Imagine a material that can capture waste heat from something as common as your car’s engine or even the warmth of your body and turn it into usable electricity. This transformative potential makes thermoelectric materials not just the subject of academic interest but also a cornerstone for future energy solutions.

At the heart of thermoelectric technology lies the Seebeck effect, a phenomenon where a temperature difference across a material creates an electric voltage. To truly appreciate this, consider how many sources of heat we encounter every day that go unused. Industrial processes, home appliances, vehicle exhausts—all produce heat that dissipates into the environment unnoticed. Thermoelectric materials offer a practical solution to reclaim this lost energy, enhancing efficiency and sustainability in diverse applications.

In this article, we will unravel the science behind thermoelectric materials, explore different types of these materials, discuss their advantages and limitations, and examine current and potential uses. By the end, you’ll have a comprehensive understanding of how thermoelectric materials are turning heat into power and shaping the future of energy technology.

What are Thermoelectric Materials?

Thermoelectric materials are special substances that can convert temperature gradients directly into electricity through thermoelectric effects, such as the Seebeck and Peltier effects. While these materials date back to discoveries in the early 19th century, their development advanced significantly during the 20th and 21st centuries.

To dive deeper, thermoelectric materials work best when they possess three important properties: high electrical conductivity, low thermal conductivity, and a high Seebeck coefficient. This combination ensures that when one side of the material is heated while the other remains cool, electrons move from the hot side to the cold side, generating an electrical current. However, this is easier said than done because materials that conduct electricity well also tend to conduct heat well, which reduces the temperature difference necessary for electricity generation. So engineering materials that break this correlation is the central challenge in thermoelectric research.

Key Properties of Thermoelectric Materials

| Property | Description | Importance |

|---|---|---|

| Seebeck Coefficient (S) | Measures voltage generated per degree of temperature difference (µV/K) | Higher values create more electricity from heat |

| Electrical Conductivity (σ) | Ability to conduct electrical current (S/m) | Higher conductivity allows easy electron flow, improving efficiency |

| Thermal Conductivity (κ) | Measures heat transfer through the material (W/m·K) | Lower values keep temperature difference across the material intact |

Together, these properties are tied in a figure of merit, called ZT, which quantifies the efficiency of a thermoelectric material. A higher ZT means better performance.

Types of Thermoelectric Materials

Thermoelectric materials come in various categories based on their chemical composition and structure. Over the decades, researchers have developed and tested a multitude of compounds to find those with better ZT values and practical usability.

Bismuth Telluride (Bi2Te3)

Among the best-known thermoelectric materials, bismuth telluride stands out because of its efficiency at room temperature, making it ideal for everyday applications like cooling and energy harvesting from moderate heat sources. Its performance is reliable, and it has been the benchmark material for decades.

Lead Telluride (PbTe)

Lead telluride is prized for its high thermoelectric efficiency at elevated temperatures, typically around 500 to 900 K. This makes it a popular choice for waste heat recovery in car engines and industrial plants where high-temperature gradients are available.

Silicon-Germanium Alloys (SiGe)

Silicon-germanium alloys are celebrated for their stability under very high temperatures—sometimes up to 1300 K. They are often employed in specialized environments like space exploration, where reliable operation under extreme conditions is required.

Skutterudites

These compounds, based on cobalt arsenide structures, offer tunable electrical and thermal properties. Their complex crystal structure allows for phonon scattering, reducing thermal conductivity and improving the ZT figure of merit.

Other Emerging Materials

Recently, new materials like half-Heusler alloys, oxide thermoelectrics, and organic thermoelectric compounds have taken center stage in research, thanks to their potential for eco-friendliness, cost-effectiveness, and enhanced thermoelectric properties.

Summary Table of Common Thermoelectric Materials

| Material | Optimal Temperature Range (K) | Advantages | Common Applications |

|---|---|---|---|

| Bismuth Telluride (Bi2Te3) | 300 — 450 | Good room temperature performance, commercially mature | Portable coolers, waste heat harvesters |

| Lead Telluride (PbTe) | 500 — 900 | High efficiency at elevated temperatures | Automotive exhaust recovery, industrial waste heat |

| Silicon-Germanium (SiGe) | 900 — 1300 | Thermal stability at very high temperatures | Space probes, high-temp sensors |

| Skutterudites | 300 — 700 | Low thermal conductivity, tunable properties | Thermoelectric power generators |

| Oxide Thermoelectrics | 500 — 1000 | Environmentally friendly, oxidation resistant | High-temp applications, harsh environments |

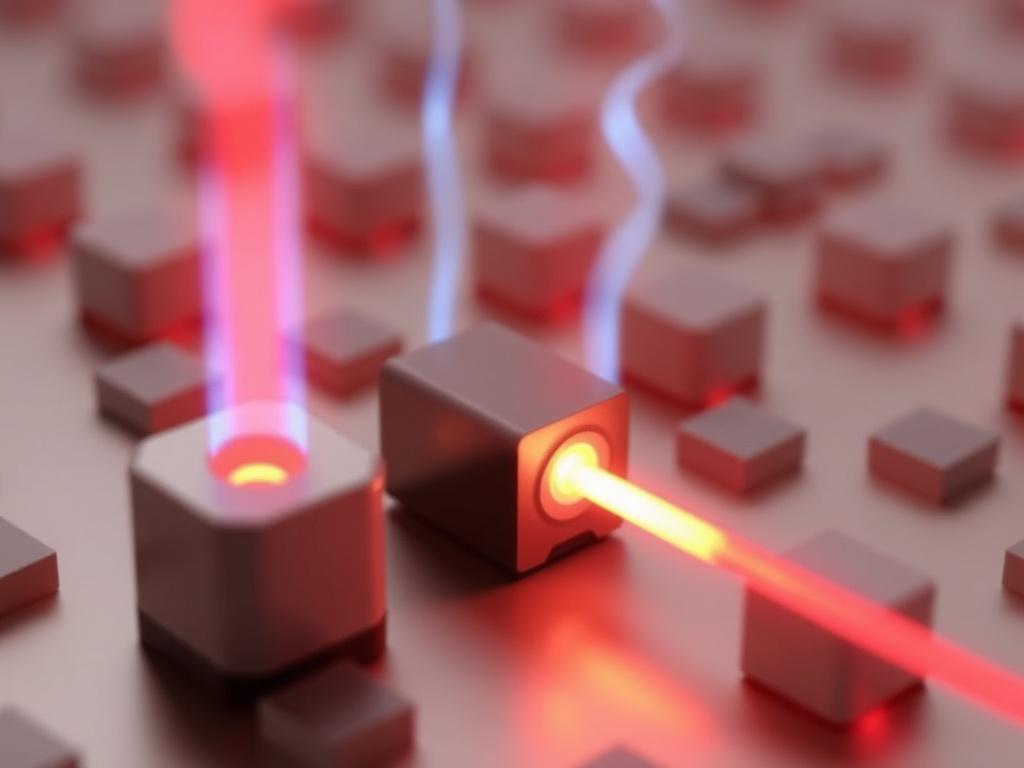

How Thermoelectric Generators Work

Thermoelectric generators (TEGs) are devices that employ thermoelectric materials to generate electricity from a temperature difference. The basic structure consists of p-type (positive charge carriers) and n-type (negative charge carriers) semiconductors connected electrically in series and thermally in parallel.

When one side of the generator is heated, it creates a temperature gradient across the thermoelectric elements. Thanks to the Seebeck effect, charge carriers diffuse from the hot side to the cold side, producing a voltage. This voltage can then be harnessed to power electronic devices or charge batteries.

A simple way to visualize this is by thinking of the thermoelectric material as a bridge where heat pushes electrons along its length, much like water flowing downhill. The greater the temperature difference and the better the material’s properties, the more electricity is produced.

Advantages of Thermoelectric Generators

- No moving parts: TEGs are silent and reliable, requiring minimal maintenance.

- Scalable: From small wearable devices to large industrial setups.

- Environmentally friendly: They convert waste heat directly, reducing fossil fuel dependence.

- Versatile: Can function in harsh or remote environments.

Limitations of Current Thermoelectric Technology

Despite their promise, thermoelectric generators currently face challenges related to efficiency and cost. The highest commercial ZT values hover around 2 to 3, but widespread adoption requires reaching ZT values above 3 or 4 for cost-effective energy conversion. Moreover, many high-performance materials contain rare or toxic elements like tellurium or lead, imposing practical restrictions.

Applications of Thermoelectric Materials

Thermoelectric materials find use in broad and fascinating fields, ranging from consumer electronics to deep-space technology. Here are some of the most exciting applications:

Waste Heat Recovery in Industry and Automobiles

One of the biggest sources of untapped energy is waste heat from industrial processes and vehicle exhausts. Thermoelectric materials are increasingly integrated into these systems to capture heat and convert it into electricity, improving overall energy efficiency and reducing emissions.

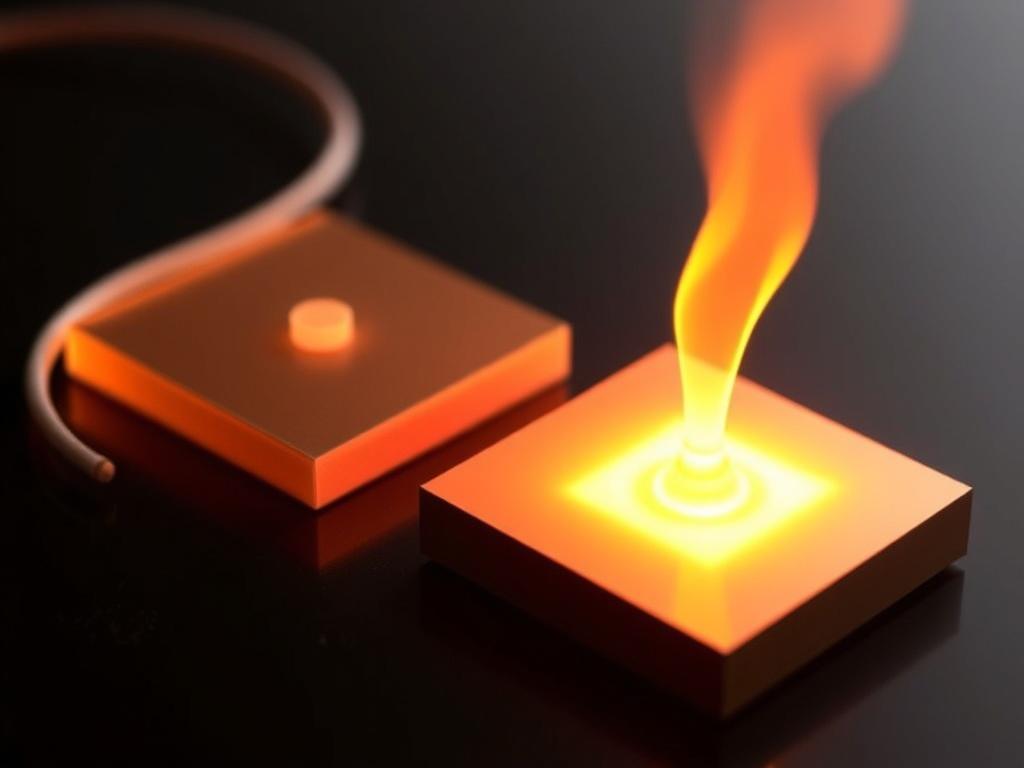

Space Exploration

Radioisotope Thermoelectric Generators (RTGs) use the heat from radioactive decay to produce electrical power in mission-critical applications such as powering spacecraft and Mars rovers. Their reliability and durability make them indispensable for long-duration space missions.

Portable and Wearable Electronics

The trend of wearable health monitors and portable gadgets is perfectly suited for thermoelectrics. For example, devices that can harvest body heat to recharge batteries free users from the dependence on conventional charging methods.

Cooling and Temperature Regulation

Thermoelectric materials are also used in Peltier coolers, which reverse the Seebeck effect. By applying electrical current, they create a heat flux, enabling compact, efficient, and vibration-free cooling. Such systems are common in electronics and laboratory equipment.

Table: Key Applications and Corresponding Thermoelectric Materials

| Application | Typical Material Used | Operating Temperature | Benefits |

|---|---|---|---|

| Automotive Waste Heat Recovery | Lead Telluride (PbTe), Skutterudites | 500 — 900 K | Improved fuel efficiency, emission reduction |

| Spacecraft Power (RTGs) | Silicon-Germanium (SiGe) | 900 — 1300 K | Reliable, long-lasting power |

| Wearables and Portable Devices | Bismuth Telluride (Bi2Te3) | 300 — 400 K | Battery extension, wireless charging |

| Electronic Cooling | Bismuth Telluride (Bi2Te3) | Near room temperature | Compact, silent cooling |

Future Trends and Innovations

Research into thermoelectric materials is one of the most dynamic fields in materials science. The aim is to enhance the ZT values, discover new eco-friendly materials, and develop scalable production methods to make thermoelectric technology more accessible.

One of the exciting areas of exploration is nanostructuring, which involves manipulating materials at the atomic or molecular scale to impede heat flow without affecting electrical conductivity. This breakthrough technique offers a path to higher thermoelectric efficiency.

Moreover, organic thermoelectrics, involving polymers and carbon-based materials, are attracting attention because of their flexibility, low cost, and environmental safety. Researchers are optimistic that combining inorganic and organic components could yield hybrid materials with superior properties.

Artificial intelligence and machine learning are also playing a pivotal role in accelerating the discovery of thermoelectric materials by predicting promising compounds faster than traditional trial-and-error methods.

Challenges Facing Thermoelectric Materials

While progress is promising, challenges remain. High-performance thermoelectric materials often contain scarce or toxic elements, limiting their widespread adoption. Cost-effective synthesis techniques are still under development to bring down production expenses.

Additionally, the durability of thermoelectric devices in real-world conditions, such as mechanical stress and thermal cycling, can impact their lifespan. Integrating thermoelectric systems with existing infrastructure also requires improvements for maximum effectiveness.

List of Challenges

- Balancing electrical conductivity and thermal conductivity

- Materials toxicity and environmental impact

- Manufacturing costs and scalability

- Device durability and mechanical robustness

- Optimizing integration with existing energy systems

How to Evaluate a Thermoelectric Material’s Performance

When assessing thermoelectric materials, it’s essential to look at their figure of merit, ZT, defined by:

ZT = (S² × σ × T) / κ

where S is the Seebeck coefficient, σ is electrical conductivity, T is absolute temperature, and κ is thermal conductivity.

The higher the ZT, the better the material’s ability to convert heat into electrical energy. Materials with ZT greater than 1 are considered useful for real-world applications, while those above 2-3 are highly efficient.

Typical ZT Values for Popular Materials

| Material | Typical ZT Range | Application |

|---|---|---|

| Bismuth Telluride (Bi2Te3) | 0.8 — 1.2 | Room temperature applications |

| Lead Telluride (PbTe) | 1.0 — 1.8 | High temperature waste heat recovery |

| Silicon-Germanium (SiGe) | 0.8 — 1.5 | Space applications |

| Skutterudites | 1.2 — 1.5 | Power generation |

Practical Tips for Using Thermoelectric Materials

If you’re considering integrating thermoelectric materials for power generation or cooling in your projects, keep these points in mind:

- Optimize temperature difference: The efficiency hinges on maintaining a large enough temperature gradient across the material.

- Pair p-type and n-type materials wisely: Matching elements with similar properties enhances performance.

- Consider mechanical stability: Ensure the device can endure thermal expansion and contraction cycles.

- Proper heat sinks: Effective heat dissipation on the cold side preserves temperature differences.

- Cost vs performance: Balance material and manufacturing costs with expected energy savings.

Conclusion

Thermoelectric materials represent a remarkable leap in our ability to harness energy that would otherwise go to waste—turning heat directly into power with no moving parts or emissions. Though challenges around efficiency, material composition, and cost remain, ongoing advances in material science, nanotechnology, and computational methods are rapidly pushing the boundaries of what thermoelectric technology can achieve. From automotive waste heat recovery to powering distant spacecraft and wearable electronics, the versatility of thermoelectric materials highlights a future where increased energy efficiency and sustainability become the norm. By understanding the science behind thermoelectric effects, recognizing the properties that make materials effective, and exploring the diverse applications, it’s clear that thermoelectric materials are more than just a technical curiosity—they are a vital piece of the energy puzzle for years to come.

Как вам статья?